what is autoclave sterilization|sterilization procedure by autoclave : distribution Autoclaving, sometimes called steam sterilization, is the use of pressurized steam to kill infectious agents and denature proteins. This kind of "wet heat" is considered the most dependable method of sterilizing laboratory equipment and decontaminating biohazardous waste. . Autoclaves use saturated steam under pressure of approximately 15 .

Dioguinho é especializado em Reality Show e Gossip em Portugal. Nasceu em 2011 e é actualizado ao minuto com toda a informação dos famosos. Quarta-feira, Fevereiro 28 2024

{plog:ftitle_list}

WEB7 de jun. de 2017 · Siófok is a town in Somogy county, Hungary, at the southern coast of Lake Balaton. The charming little town is one of the most popular holiday resorts in Hungary. The population is around 25,000 people but in the summer season there is always another 200,000 people spending their vacation there at the same time. The name of the .

Learn how autoclave kills microorganisms using saturated steam under pressure. Find out the components, types, procedure, control, precautions and us. Image 1: Parts of a vertical autoclave steam sterilizer. Over the past few months, because of the Covid-19 pandemic, there has been a great rise in the usage of the Autoclave as it is a simple and effective equipment to use. . A: Steam (autoclave) sterilization, is renowned for its efficiency, speed, and environmental safety compared to methods like ethylene oxide sterilization or radiation. It's particularly effective for materials that can . Autoclave sterilization is a method of sterilization that uses heat from pressurized steam to kill microorganisms. Autoclave sterilization is often used to sterilize medical and laboratory .

Sterilization Cycle Verification. A sterilization process should be verified before it is put into use in healthcare settings. All steam, ETO, and other low-temperature sterilizers are tested with biological and chemical indicators upon installation, when the sterilizer is relocated, redesigned, after major repair and after a sterilization failure has occurred to ensure they are . Autoclaving, sometimes called steam sterilization, is the use of pressurized steam to kill infectious agents and denature proteins. This kind of "wet heat" is considered the most dependable method of sterilizing laboratory equipment and decontaminating biohazardous waste. . Autoclaves use saturated steam under pressure of approximately 15 .

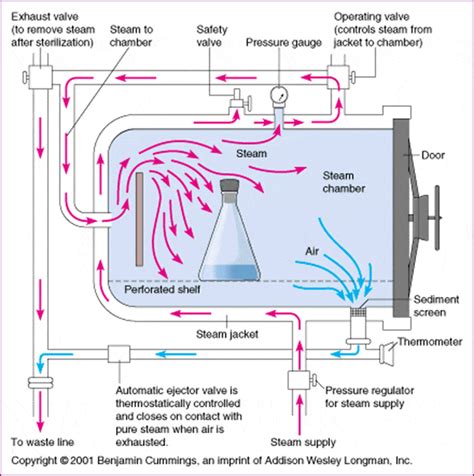

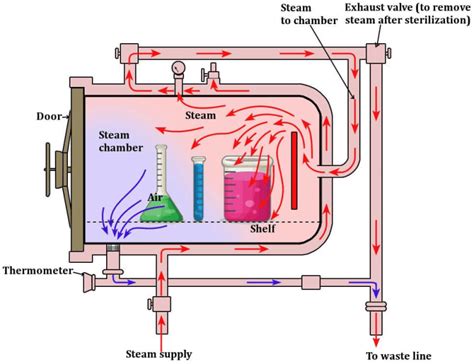

An autoclave is a piece of equipment used in nearly all scientific fields and industries. It uses high-pressure steam to sterilize objects that can withstand the high temperatures. It turns hazardous waste into non-hazardous waste, and it’s responsible for the level of sterilization that’s able to be achieved today. What Is An Autoclave? An autoclave is a machine that is used to eradicate biohazardous waste from the surface of tools or instruments. It was invented by Charles Chamberland in 1884. Autoclaves sterilize or disinfect through physical means by using pressure, temperature and steam. They are often referred to as steam sterilization machines. Autoclave sterilization is a cornerstone of modern medical practices. It’s a method used to kill or eliminate harmful microorganisms such as bacteria, viruses, and spores from medical devices and other materials, and involves subjecting these items to high-pressure saturated steam at elevated temperatures. Figure 3. 1. Vessel. The vessel is the main body of the autoclave and consists of an inner chamber and an outer jacket. Laboratory and hospital autoclaves are constructed with “jacketed” chambers (see Figure 4), where the jacket is filled with steam, reducing the time that it takes to complete a sterilization cycle and reducing condensation within the chamber.

The maintenance of aseptic conditions is an absolute requirement in tissue culture labs. Autoclave, also known as steam sterilizer, is the most effective machine for the sterilization of lab equipment, water, or media. The machine uses steam under pressure to kill bacteria, viruses, and spores present in/on the equipmeThe autoclave sterilization cycle consists of three phases: [3] Purge Phase, Exposure (Sterilization) Phase, and Exhaust Phase – these phases are completed in around 1-1.5 hours. [11] The autoclave cycle time frame refers to the exposure phase, which varies based on the size, shape, density, weight, and material composition of the items being . An autoclave is a piece of equipment used to sterilize objects using high-pressure steam. Many fields and industries utilize autoclaves, including medicine, tattoo parlors, dentistry, and most . Autoclave sterilization works by using heat to kill microorganisms such as bacteria and spores. The heat is delivered by pressurized steam. Pressurization allows the steam to reach the high temperatures that are required for sterilization. According to Centers for Disease Control .

Conclusion. Autoclaves are powerful tools in the fight against microbial contamination and the sterilization of laboratory equipment and waste. By harnessing the power of steam, pressure, and time, autoclaves can effectively eliminate microorganisms and spores, ensuring a safe and sterile environment.

use of autoclave in laboratory

sterilization procedure by autoclave

Autoclaves use water, pressure, and heat to create superheated steam that kills microorganisms and spores. Autoclaves at Princeton are used to decontaminate certain biological waste and sterilize media, instruments and .The way chemical indicators are used with an autoclave process depends on the indicator Type and sterilization cycle. Chemical indicators should be used in conjunction with physical monitors and any other appropriate measure of sterility assurance. . 1 ANSI/AAMI ST79 Comprehensive guide to steam sterilization and sterility assurance in health .

Sterilization tape, also known as autoclave tape or indicator tape, is an essential tool used to provide visual confirmation that items or surfaces have been subjected to a specific sterilization process. It serves as a crucial indicator of .

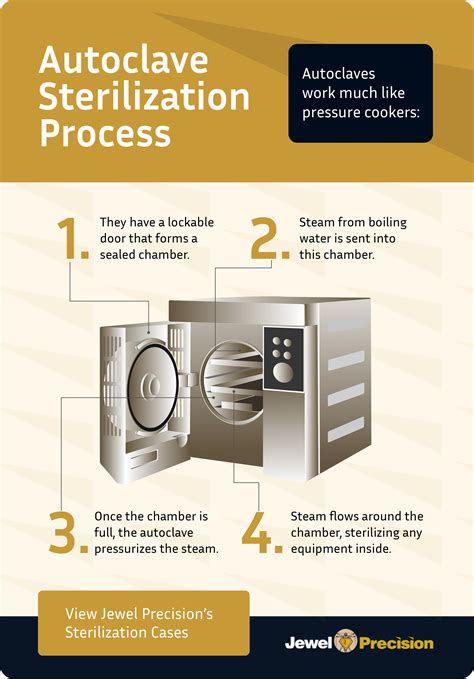

Autoclaves provide a physical method for disinfection and sterilization. They work with a combination of steam, pressure and time. . Incorrect selection of cycle may damage the autoclave, cause liquid to boil over or bottles to break. Start your cycle and fill out the autoclave user log. A completed cycle usually takes between 1 to 1.5 hours.Autoclaves provide a physical method for disinfection and sterilization. They work with a combination of steam, pressure and time. Autoclaves operate at high temperature and pressure in order to kill microorganisms and spores. They are used to decontaminate certain biological waste and sterilize media, instruments and lab ware. Regulated medicalHow does an autoclave work? Irrespective of whether it is a small tabletop autoclave unit or an industrial-sized bulk autoclave unit, all steam autoclaves operate using principles similar to those of a kitchen pressure cooker- that is, the chamber is sealed and all air within is replaced by steam. Three factors are critical to ensure successful steam sterilization in an autoclave - time .

What is an autoclave? Autoclaves are also known as steam sterilizers, and are typically used for healthcare or industrial applications. An autoclave is a machine that uses steam under pressure to kill harmful bacteria, viruses, fungi, and spores on items that are placed inside a pressure vessel. The precursor to the self-locking steam sterilizer, or autoclave, was used to cook food and operated in much the same way as today's pressure cooker. With the advancement of the autoclave, medical . Steam sterilizers — also known as autoclaves — are an essential piece of equipment in any laboratory, research, or healthcare setting, ensuring sterility for important equipment and instruments. Autoclaves are available in a wide array of designs, each tailored for specific applications, ranging from small-scale laboratory sterilization to .

Sterilization (British English: sterilisation) . Most autoclaves have meters and charts that record or display information, particularly temperature and pressure as a function of time. The information is checked to ensure that the conditions required for sterilization have been met. In general, for aqueous preparations, a microbiologically – Validated steam sterilization process that delivers, in total ( including the heating up & cooling down phases of the sterilization cycle ), an Fo-Value of Not less than 8 to every container in the autoclave load is considered satisfactory. All validated steam sterilization cycles provide efficacious autoclave sterilization when used according to manufacturer's instructions, but dynamic air removal cycles are preferred because they are more efficient than gravity cycles at removing air from the load. Anatomy of a Steam Sterilization Cycle

Medical devices are sterilized in a variety of ways including using moist heat (steam), dry heat, radiation, ethylene oxide gas, vaporized hydrogen peroxide, and other sterilization methods (for .

principle of autoclave sterilization

kruss polarimeter p3000 manual

Melhores contas gratuitas do OnlyFans. MelRose: Atriz possui mais de 1.100 fotos e vídeos em sua página gratuita na plataforma, conforme o site norte-americano. Riley: Modelo compartilha vídeos de strip-teases completos, brincadeiras quentes e um conteúdo apontado como "irrestrito e divertido", conforme levantamento.

what is autoclave sterilization|sterilization procedure by autoclave